Kepler Gold Laser Welding Machine

Kepler Gold Laser Welding Machine Specification

- Humidity

- 5% - 85% RH

- Frequency

- 50 / 60 Hz

- Number of Specimens

- 1 - 5

- Application

- Jewelry Welding / Gold & Silver Processing

- Temperature

- 5C - 40C

- Response Time

- <1 second

- Power Supply

- 220V / 50Hz

- Interface Type

- RS232 / USB

- Max Height

- 500 mm

- Measuring Range

- 0.01 mm to 10 mm

- Specimen Size

- As per custom requirement

- Test Range

- Dynamic and Static

- Automation Grade

- Semi-Automatic

- Port Size

- Standard Industrial Ports

- Operating Voltage

- 220V AC

- Display Type

- LCD Touchscreen

- Resolution

- 0.001 mm

- Features

- Energy Efficient, Micro-Spot Welding, Stable Beam Quality, Low Heat Output

- Mounting Type

- Table Top

- Accuracy

- 0.01 mm

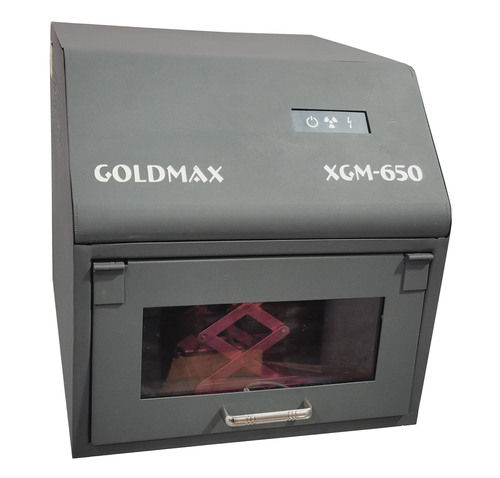

- Equipment Type

- Laser Welding Machine

- Gas Pressure

- 0.2 - 0.5 MPa

- Usage

- Industrial / Jewelry Workshops

- Capacity

- 100W / 200W / 300W Options

- Machine Weight

- 75 kg

- Test Speed

- Adjustable

- Test Width

- Customizable as per requirement

- Test Stroke

- 150 mm

- Control Mode

- Touch Screen PLC Control

- Laser Type

- Pulsed YAG Laser

- Protective Atmosphere

- Argon Gas Optional

- Pulse Energy

- Up to 60 Joules

- Focal Length

- 70 mm 150 mm (Interchangeable Lens)

- Pulse Width

- 0.1 10 ms adjustable

- Laser Wavelength

- 1064 nm

- Work Environment

- Dust-Free Clean Room Preferred

- Optional Accessories

- Microscope, CCD Camera, Extra Nozzles

- Spot Size

- 0.2 mm 2 mm

- Dimensions

- 600 x 360 x 360 mm (LxWxH)

- Safety Features

- Overheat Protection, Emergency Stop Switch

- Cooling Method

- Built-in Water Cooling System

About Kepler Gold Laser Welding Machine

Specification

| Autodiagnosis System | Automatic with warnings on display |

| Average Power | 100 W |

| Dimensions | 84x45x50 mm |

| Display | Colorful graphic display 5,7 inch |

| PC Connection | USB |

| Peak Power | 10 kW |

| Power | 4.5 kW |

| Power Supply | 230V 50/60Hz, 10A |

| Programs | 50 programs |

| Pulse Energy Max | 130 J |

| Pulse Width | 1-5 ms |

| Size | 500 (W) x 515 (H) x 660 (D) mm |

| Spot Diameter | 0.2 - 2.0 automatic regulation with steps of 0.1 |

| Working Area Lighting | Cold light source (led) |

| Brand | Kepler |

| Weight | 65 kg |

Enhanced Precision for Jewelry Applications

With a minimum spot size of 0.2 mm and a focus on accuracy (0.01 mm), the Kepler Gold Laser Welding Machine is tailored for intricate jewelry and precious metal repairs or fabrication. Its micro-spot capabilities ensure seamless welds, while dynamic test ranges support diverse task requirements and specimen sizes. The adjustable pulse width and length further elevate welding flexibility, catering specifically to luxury craftspeople and industrial users.

User-Friendly Touch Screen Operation

Equipped with an LCD touchscreen and PLC control, the machine ensures a simple and efficient user experience. Operators can easily manage welding parameters, monitor process progress, and switch between test modes. The interface supports USB and RS232 connectivity, enabling smooth data transfer and integration with existing workshop systems.

Safety and Environmental Adaptability

Safety is a key priority, with overheat protection and an emergency stop switch included. The built-in water cooling system maintains optimal temperature during extended use. For best performance, a dust-free clean room is preferred, and argon gas protection is optionally available. The system functions reliably within a broad humidity (5%85% RH) and temperature (5C40C) range.

FAQs of Kepler Gold Laser Welding Machine:

Q: How does the Kepler Gold Laser Welding Machine enhance welding precision for jewelry and fine metal work?

A: The Kepler Gold Laser Welding Machine uses a pulsed YAG laser with spot sizes as small as 0.2 mm and accuracy of 0.01 mm, allowing for micro-spot welding and exceptional control. This precision is ideal for delicate gold and silver jewelry repairs or fabrication, ensuring neat and strong welds even on intricate pieces.Q: What types of applications is this machine best suited for?

A: This machine is specifically designed for jewelry welding and gold or silver processing, but it is also suitable for other fine metalwork tasks where accuracy and minimal heat impact are essential. Its dynamic and static test ranges accommodate both industrial manufacturing and artisan workshop needs.Q: When is using argon gas as a protective atmosphere recommended?

A: Argon gas is optionally available and is recommended when working with reactive metals or when oxidation-free welds are required. It helps in creating a clean environment around the welding spot, enhancing weld quality and appearance.Q: Where can the Kepler Gold Laser Welding Machine be installed and operated?

A: The machine is designed for table-top installation in industrial facilities or jewelry workshops. For optimal performance and longevity, it should be operated in a dust-free clean room with ambient humidity between 5%85% RH and temperatures from 5C to 40C.Q: What is the process for adjusting welding settings on this machine?

A: Users can set pulse energy, width, and spot size directly through the LCD touchscreen PLC controller, which also allows for selecting test speed, customizing test widths, and switching control modes. The interface is intuitive, enabling fast parameter changes to adapt to various welding tasks.Q: How does the machine ensure safety during operation?

A: It incorporates overheat protection and an emergency stop switch. The built-in water cooling system prevents overheating, while optional accessories like microscopes and CCD cameras can improve operator accuracy and monitoring during welding.Q: What are the benefits of using this laser welding machine over traditional methods?

A: Unlike conventional welding, laser welding produces stable beams, lower heat output, and minimal distortion. It allows for micro-spot welding, suitable for intricate works, while being efficient in energy use and providing rapid, precise results. The semi-automatic operation and digital controls further improve workflow efficiency and product consistency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gold Laser Welding Machine Category

Eco Gold Laser Welding Machine

Application : Gold and Silver Jewellery Welding

Power Supply : AC 220 V, 50/60 Hz

Usage : Metal Welding for Jewellery

Features : Low power consumption, high precision, compact design

Mounting Type : Desktop

Humidity : 5%85%

Gold Laser Welding Machine

Application : Testing & Measurement

Power Supply : Electric

Usage : Industrial

Features : Accurate

Mounting Type : Free Stand

|

Microanalytik Instruments Pvt. Ltd.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry